Evercloak poised to Transform Building Cooling with Nanofilms

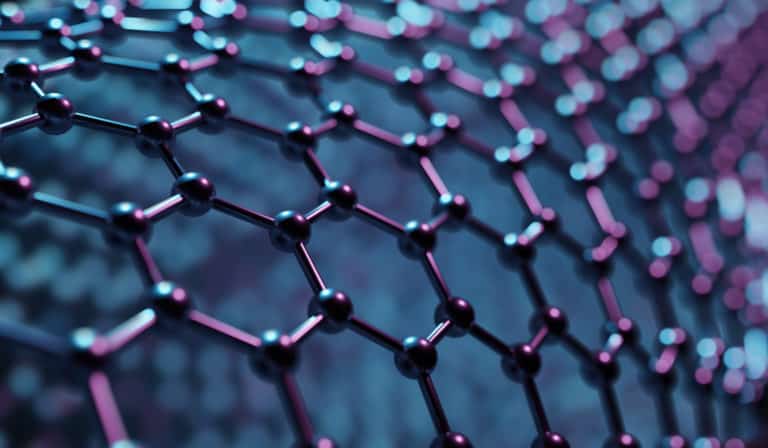

Evercloak has a breakthrough approach to how we cool. The company’s ultra-thin nanofilms can curb greenhouse gas emissions by greatly reducing the energy needed for air conditioning.

A Future of Cooling report shows HVAC energy use counts for about 20 percent of the total electricity used around the world, and demand is expected to triple by 2050. Growing demand for AC is a critical but overlooked energy issue, and according to NASA, the last several years have been the warmest on record.

“Through the use of ultra-thin nanofilms that act as membranes to efficiently remove humidity. Evercloak’s dehumidification systems will enable smaller footprints to support retro-fit markets, better energy efficiency, and performance improvements that will revolutionize climate technology,” says Evelyn Allen, CEO, and Co-founder of Evercloak.

Evercloak has been developing this technology over the past two years with support from the Government of Canada’s Breakthrough Energy Solutions Canada program. The federal government announced Evercloak as one of 10 cohort winners through the program in February 2020. This first-of-its-kind public-private initiative in Canada was launched under Natural Resources Canada’s Energy Innovation Program in partnership with BDC and Breakthrough Energy, a group of investors created by Bill Gates in 2015 to address climate change. Since being awarded this grant, Evercloak has been working to enhance the pace and scale of its clean technology with persistence.

Evercloak’s team, led by research engineers specializing in material science, began working on the project in April 2020, with the goal of enhancing Evercloak’s membrane technology and scaling up production. Evercloak’s patent-pending manufacturing process enables low-cost and large-area membrane production, unlocking breakthrough commercial use cases that are not possible today.

When Evercloak set out to make this technology a reality, their team had three main objectives. First, to demonstrate a high-performing membrane that could help make a small system compared to what’s available on the market. Second, to integrate the membrane into a prototype system, which would reduce the energy load on cooling systems. Third, to advance the scale-up production of the membrane manufacturing process.

Based in Waterloo, Ontario, Evercloak aims to revolutionize industrial processes and drive clean technology with the world’s thinnest and most uniform nano-coatings. By re-thinking the way 2D materials are manufactured, Evercloak is creating scalable and commercially viable opportunities to transform everything from energy storage to water desalination and address the world’s most pressing environmental challenges.

The idea of this project is to scale up production for large-area coatings and develop an application that can use Evercloak’s water vapor selective coatings to improve HVAC coatings so that air coming into buildings can be dehumidified while reducing the energy load by AC systems.

This is an active, ongoing project, and there is still more work to be done. However, since the start of the project, Evercloak’s team has noted significant progress in the development of the membrane, including the membrane production scale up three times the original size.

“Being able to coat larger widths and reach the energy-saving milestones determined at the start of the project has been exciting,” says Allen.

From a commercial standpoint, Evercloak is working and connecting with strategic HVAC manufacturers, engineering firms, and the building sector. The feedback is excellent and players throughout the value chain are expressing a need for more sustainable humidity management solutions.

This is particularly true in parts of the world that experience heat waves and where humidity is a significant concern in commercial buildings, such as in the southeastern United States, among other regions. Conventional AC systems may not be able to efficiently cool these buildings while also reducing humidity to comfortable levels. Evercloak’s technology would help achieve comfortable humidity levels while avoiding too much strain on AC systems.

“Our team is working to scale our membrane manufacturing production, while forward integrating our membrane into assembly-level HVAC prototypes with testing on-site,” says Allen.

Over the next few decades, heat waves will become increasingly common in many parts of the world. If industries do not adopt new technologies to curb greenhouse gas emissions, daily temperatures are expected to rise by at least five degrees Fahrenheit by the middle of this century. Extreme heat combined with high humidity is not only dangerous to our health, but it will also continue to contribute to higher energy costs associated with cooling our buildings and indoor spaces.

Revolutionizing AC and dehumidification systems is the first step toward a better future. With advanced material innovations, Evercloak is poised to revolutionize the dehumidification market, enabling the development of clean and efficient commercial solutions addressing the climate crisis.